In this article, I will explain how to transform air-cooled miners into liquid-cooled beasts! Liquid cooling is the best upgrade to get away from noisy fans, overheating chips, and inefficiency.

I will describe the fundamental parts and the conversion process to optimize your miner and make it powerful, efficient, and cool.

What Is Air vs. Liquid Cooling?

Air cooling relies on fans blowing air over heat sinks, which dissipates heat from your miner’s components. It’s inexpensive, easy to implement, and quite popular.

However, can generate loud noise and limit overclocking potential. Compared to this, liquid cooling is more efficient and complex.

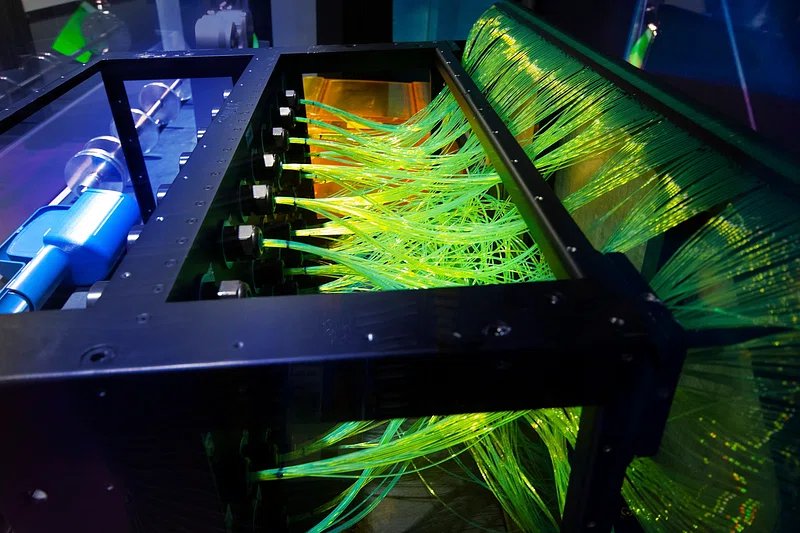

It circulates liquid coolant through water blocks attached to the hot components. Heat is carried away to a radiator, providing efficient heat dissipation.

This method is more costly, which liquid cooling is best suited for high-demand or overclocked mining rigs.

Liquid cooling’s quieter operation, lower temperatures, and better performance can improve overclocking potential and greatly facilitate complex mining operations.

How To Convert an Air-Cooled Miner into a Liquid-Cooled Beast!

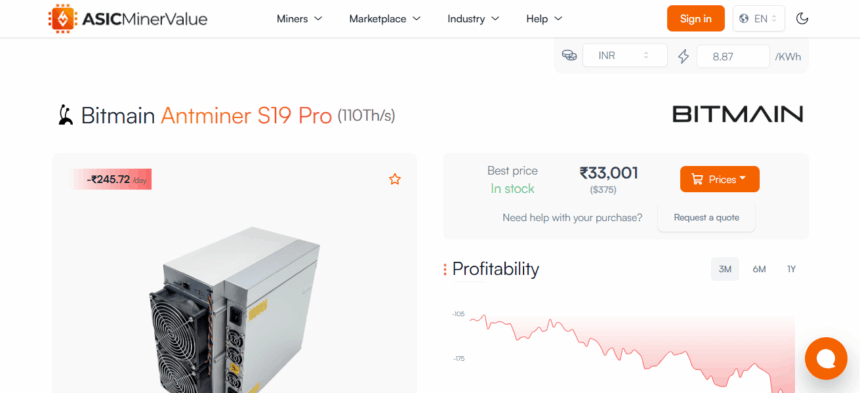

Example: Converting a Bitmain Antminer S19 to Liquid Cooling

Step 1: Gather Your Components

- Water blocks compatible with S19 ASIC chips

- Pump and reservoir

- 240mm radiator with fans

- Tubing, fittings, and clamps

- Non-conductive coolant

- Thermal pads and thermal paste

Step 2: Disassemble the Miner

Carefully remove the stock fans and shrouds. Detach the hash boards while handling them gently to avoid damaging chips.

Step 3: Install Water Blocks

Apply thermal paste or pads to the ASIC chips, then secure water blocks on top. Ensure full contact for optimal heat transfer.

Step 4: Set Up the Cooling Loop

Connect tubing from water blocks to the pump, reservoir, and radiator. Make sure the flow path avoids kinks and maintains proper circulation.

Step 5: Fill, Test, and Monitor

Start with water for a leak test. Once confirmed, add coolant and power on the miner, monitoring temperatures closely. Adjust fan speeds and flow if needed.

Result:

Antminer S19 is performing cooler and quieter and maintains a higher performance level now. Its transformation from an air-cooled rig to a liquid-cooled beast is a noteworthy accomplishment!

What is the main difference between air-cooled and liquid-cooled miners?

The distinction between air-cooled and liquid-cooled miners is based primarily on heat management methods:

- Air-cooled miners deploy fans to dissipate heat from chips and heat sinks using air flow. They are easier to maintain, cost-effective, and simpler, but they can be loud and might not efficiently cool components during peak that is more than overload.

- Liquid-cooled miners utilize pumps to move coolant through a closed circuit that consists of water blocks that absorb heat from chips. It is more powerful, overclocking is made possible, and allows elevation in performance but comes at a higher price and complexity.

Is it safe to convert my miner to liquid cooling?

It is safe to convert an air-cooled miner to liquid cooling as long as it is done correctly. Liquid cooling requires special handling for sensitive electronic components.

It is also important to avoid leaks when installing water blocks, tubing, and fittings; leaks can short-circuit the components.

Using the right coolant and properly fitted the coolant flow direction and return reduce the chances of problems.

The task requires a high level of patience and focus because minor mistakes can lead to the entire hardware failing and expensive repairs. Therefore, the focus needs to be on safe and precise activities.

Planning Your Conversion

- Assessing your miner model for compatibility: Determine whether your miner’s design and parts can accommodate water blocks and tubing.

- Budgeting: cost of radiator, pump, coolant, fittings, tubing, thermal pads: Ensure the cost of all components for liquid cooling is within your planned spending.

- Safety considerations (water/electricity risks, warranty issues): Ensure the risks of leaking and electrical hazards, warranty voiding.

- Required tools (screwdrivers, thermal paste, clamps, etc.): Ensure all tools are on hand to set up and put in place the liquid cooling system.

Components Needed for Liquid Cooling

Water Block(s) for ASIC Chips or GPUs: Transfers heat from chips and manages temperatures with coolant.

Pump and Reservoir: Maintains flow and prevents overheating by circulating coolant throughout the system.

Radiator and Fans: Keeps the system cool by dissipating heat and coolant into the air.

Tubing and Fittings: Connect all components and ensure the coolant flows smoothly and leak-free.

Coolant Type and Additives: Properly prevents system corrosion and touch heat coolant carrier for system longevity.

Optional: Temperature Sensors and Monitoring Equipment: Optimizes system temps and early detects troubleshooting by tracking temperatures.

Optimizing Your Liquid-Cooled Miner

Optimizing coolant flow and radiator positioning:

Vary the flow rate and reposition radiators to enhance heat dissipation and promote even cooling to prevent hotspots and subsequent cooling miner performance reduction.

Adjusting fan curves for noise and efficiency

Set fan speeds to cooling thresholds to reduce noise and avoid overheating while controlling excessive energy usage and maintaining system components to safe operating levels.

Overclocking with safe temperatures

Increase the clock speed and hash rate while observing temperatures to avoid system instability and overheating. This will prevent overheating and damage hardware to system.

Scheduled maintenance (leak check, coolant change)

Check for leaks to replace and clean coolant, components, tubing and fittings to prevent corrosion, promote performance and prolonged operational lifespan for the miner.

Troubleshooting Common Issues

Leaks and corrosion: Check coolant leak corrosion and tub fittings corrosion.

Pump or flow failure: Check system pump operation and proper coolant flow circulation.

Overheating or temperature spikes: Continuously monitor temperatures; flow, fans, and radiator adjust.

Electrical shorts or malfunctions: Keep liquid away in electronics; verify wiring and connections.

Conclsuion

Transforming air-cooled miners into liquid-cooled monsters boosts performance, minimizes noise, and enhances the durability of the hardware.

The benefits—lower temperatures, stable operation, and the opportunity to overclock—make the effort and meticulous safety planning for the necessary components worthwhile.

Your liquid-cooled miner will require monitoring and maintenance to achieve the desired reliability and optimal efficiency.

FAQ

Is liquid cooling safe for miners?

Yes, if installed carefully with proper components and leak prevention.

What components are needed?

Water blocks, pump, reservoir, radiator, tubing, fittings, and coolant.

Will it void my warranty?

Most likely, as disassembly and modifications usually void manufacturer warranties.

Can I overclock after conversion?

Yes, lower temperatures allow safer overclocking and higher hash rates.

How do I prevent leaks?

Use quality fittings, clamps, and test with water before adding coolant.

How often should I maintain the system?

Check for leaks and replace coolant every 6–12 months.